3D printing has had a number of early successes in healthcare, whether it’s helping surgeons prepare for operations or even reducing the need for animal testing.

3D printing has had a number of early successes in healthcare, whether it’s helping surgeons prepare for operations or even reducing the need for animal testing.

A recent paper highlights yet another use case, outlining the process by which 3D printing can be used to manufacture heavily used items, whether it’s ports to drain bodily fluids, implantable bands, balloons, soft catheters, slings and meshes.

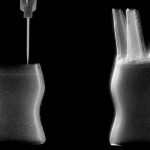

“Our new material provides support for the liquid silicone as it is 3D printing, allowing us create very complex structures and even encapsulated parts out of silicone elastomer,” the authors say.

The team believe that 3D printing could pave the way for new therapeutic devices that are capable of releasing drugs, or even small molecules to help guide tissue regeneration or help diseased organs. They are also confident in the potential cost savings available.

Cost savings

“The public is more sensitive to the high costs of medical care than ever before. Almost monthly we see major media and public outcry against high health care costs, wasteful spending in hospitals, exorbitant pharmaceutical costs,” they say. “Everybody agrees on the need to reduce costs in medicine.”

The work has been a long time in gestation, with this latest paper born out of a previous project looking into printable organs and tissues. In that work, the team discovered a new method for manufacturing soft materials using 3D printing and microscopic hydrogel particles as a medium. The project encountered a challenge however in that the materials were water-based and therefore incompatible with oily substances like silicone. The team overcame this problem by developing an oily version of the microgels.

“Once we started printing oily silicone inks into the oily microgel materials, the printed parts held their shapes,” they say. “We were able to achieve really excellent 3D printed silicone parts – the best I’ve seen.”

The ultimate goal is to make organs and tissues via 3D printing, but it’s a goal that they accept is many years away, but printing medical implants is a much more accessible short-term goal.

“The reality is that we are probably decades away from the widespread implanting of 3D printed tissues and organs into patients,” they reveal. “By contrast, inanimate medical devices are already in widespread use for implantation. Unlike the long wait we have ahead of us for other 3D bioprinting technolgies to be developed, silicone devices can be put into widespread use without technologically limited delay.”

It’s a fascinating project, and you can see the process in action via the video below.