I wrote recently about the potential for 3D printed houses, and it’s undeniable that the range of things that can be manufactured using additive approaches is increasing at a rapid rate.

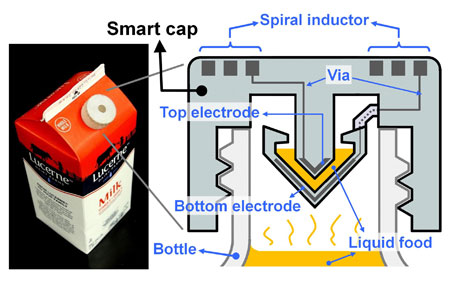

A recent project has attempted to utilize 3D printing to help reduce food wastage. The project, which was documented in a recently published paper in Nature, sees a ‘smart cap’ produced for milk cartons that can detect when the milk is going off.

Sensitive electronic components

The first generation of 3D products have largely been quite basic and have lacked any kind of sensitive electronic components.

“Our paper describes the first demonstration of 3D printing for working basic electrical components, as well as a working wireless sensor,” the authors say. “One day, people may simply download 3D-printing files from the Internet with customized shapes and colors and print out useful devices at home.”

The device combines 3D printed plastic with embedded electronics to wirelessly monitor the freshness of the milk in your fridge.

To achieve this the researchers had to modify the traditional approach to 3D printing. Ordinarily polymers are used, but because these are poor conductors of electricity they are not suitable for more complex creations.

The authors got around this by combining polymers and wax at the outset, before then removing the wax and replacing it with liquid metal.

They then inserted the components into a plastic milk carton cap and attempted to monitor the milk for signs of spoilage. The cap was kitted out with a capacitor and inductor, and when the carton was flipped some of the milk would get trapped in the capacitor for monitoring.

The authors left the carton in room temperature for 36 hours, and the circuit was capable of detecting an increase in bacteria by the changes in electrical signals produced.

The changes were monitored via a wireless radio frequency probe at periodic intervals, although there would appear clear potential for the carton to be monitored via an AI based device instead.

The authors are looking to develop the technology further, especially in healthcare, where, for instance, implants can be fitted with embedded circuitry to monitor things such as blood pressure, muscle strain and drug concentrations.

Exciting times indeed, and I feel this is a trend that has some way to go yet.

That's pretty neat I have to say. They could use that in the supermarkets so they'd not try and flog customers produce that is clearly off before it leaves the shelf!

Haha, can you ever really see the supermarkets owning up to that? My local Tesco would never stock anything!

That would be a great application for it, but it's tough to see a supermarket going down that route any time soon (sadly).